We are known for incorporating latest technologies to constantly upgrade our products, which in turn benefits our customers.

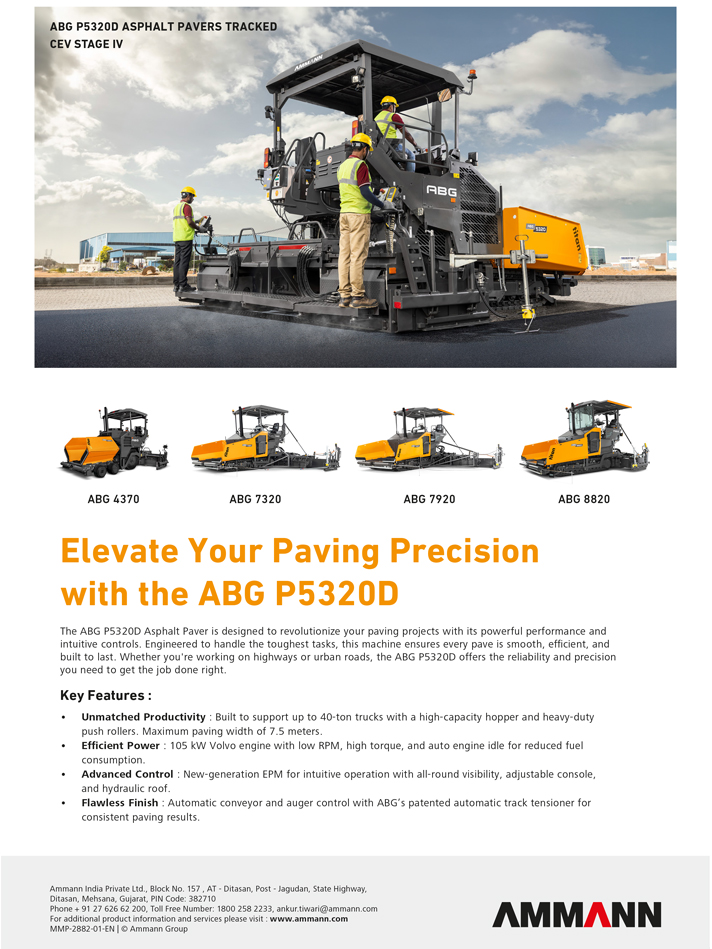

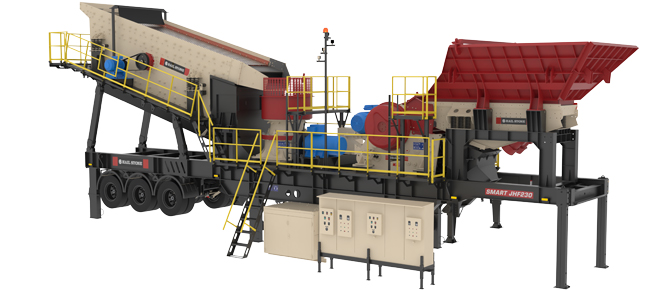

Hailstone is a fast-paced organisation specialised in engineering, designing, fabrication and manufacturing of capital equipment in crushing, mining, screening etc. The company offers a broad range of stationary and mobile solutions with customised designs to meet specific application requirements.

In an exclusive interview to CONSTRUCTION OPPORTUNITIES, WILLIAMS RJ, MANAGING DIRECTOR, HAILSTONE INNOVATIONS, gives an overview on the Crushing & Screening equipment industry, his company’s emphasis on technology, research, design, innovation, initiatives taken by his company in terms of upskilling the operators and a lot more.

Briefly give us an overview of the Crushing & Screening equipment industry, the latest trends and market dynamics? What are the types of crushing & screening equipment currently most in demand?

The crushing and screening equipment market in India actually consists of both organized and unorganized sector. While it is difficult to put a value to this market, the crushers and screens market in India is estimated to be close to 30 billion per year. This is especially for aggregates, which is 100 TPH and above. Out of this total figure, track mounted plant is estimated to approximately6 billion, Wheel mounted plant at 10 billion and14 billion for skid mounted and unit equipment. The demand for crushers and screens is increasing because of the construction and infrastructure development projects like roads, dams and railways. The usage of river sand has been banned in many states and that is also a major factor. Rapid urbanization is another factor. There is a huge market for all our products and it is difficult to identify one single product which has the most demand.

Detail us on your CSE equipment, types and capacities. Please provide details on your emphasis on technology, research, design and innovation?

We are a fast-paced organization specialized in engineering, designing, fabrication and manufacturing of capital equipment in crushing, mining and screening. We have a total of 21 products and 150+ models which caters to the unique needs of customers. We constantly invest in the company, improving quality at every stage of the process and implement innovative technologies. The focus is always on quality and innovation and we offer the customers the best solutions for their needs.

Intelligent machines, telematics and IoT are becoming a trend with equipment, your comments. Cutting edge technology featured in your machines. What distinguishes your equipment from competitors?

We are known for incorporating latest technology to constantly upgrade our products, which in turn benefits our customers. Our SMART machines are winning appreciation all over. The automation feature our machines makes life easier for stakeholders.

We stand out among the crowd because of our product quality, latest technology, ease of operation, best-in-class safety and maintenance features.

Factors such as safety, operator comfort, ease of operations are crucial. What are the steps undertaken by you for providing the same.

All the 21 products and 150+ models from Hailstone have safety features as per the prescribed norms. Our R & D engineers always ensure that the safety feature tops the list whenever they design a new project. Not just that, customers who have been using our machines tell us about how easy it is to operate our machines and we are glad to hear that.

Detail us on your new launches, what are the new technological advancements in these machines.

We have launched mobile series products in the first half of 2024 and we plan to launch more. Understanding the market demands, our R & D team is coming up with new products with advanced technologies, the announcement of which will be made soon.

Details us on the initiatives taken by your company in terms of skilling the operators.

We are focused on maximizing the skill set and capability of the existing workforce. Our workers are trained in maintenance, repair and operations (MRO) solutions to save costs and improve efficiencies. Training ups the safety quotient of the site and also increases productivity. More than anything else, the reliability factor increases. Workers who work with the equipment must certainly have the necessary knowledge and skill. They must also be trained for maintenance so that equipment performance and reliability can be increased. We have our own customized training programmes with reviews of common failure causes and prevention methods to maximize efficiency and effectiveness of maintenance operations. The best practices in MRO and in latest technologies are taught through these training sessions. Hands-on training and in-plant pre-visit and follow-up give the workforce the knowledge and tools to save time and improve reliability and equipment safety. Workers in Maintenance, Repair and Operations, quarry managers and maintenance engineers need upskilling to deliver cost savings and to provide reliability to the plant.

Future outlook on the industry and from a company perspective

The government is focused on improving infrastructure and there are various projects that have been announced. With lot of investment being done in the infrastructure sector, I see a bright future for the construction equipment as well as crushing and screening industry.