Page 39 - January_2023

P. 39

COVER STORY

• Automated insertion of longitudinal joint tie bars to prevent

the slabs from drifting apart

• Inset paving mould suitable for mounting between the track SPOTLIGHT

units, underneath the machine

• Pivoting legs for full adjustment of the track units to the

conditions prevailing on site

Kleemann screens and scalpers did the groundwork. They

produced the aggregates.

Different models of Vögele pavers were responsible for the DLC (dry

lean concrete) pavement on various sections including approach

roads and toll areas. They laid a surface with a thickness of 150

mm.

Hamm tandem rollers ensured an even underground. They also

compacted the shoulders on both sides of the expressway’s lanes.

The Wirtgen equipment was the last in line. The slipform pavers SP

1600 and SP 94 laid the concrete surface followed by a TCM 180

that added the finishing touches to the brand-new concrete lanes.

Wirtgen Group service impresses on site

When it comes to the experience and day-to-day handling of their

equipment, there is unanimity: Everyone is more than happy with

the performance of the machines. “They are doing very well, and

we are extremely satisfied with their services,” said Neeraj Sharma,

Quality Incharge (Sr. Manager) at Apco Infratech, responsible

for package 5. “They are good in technology, quality and output.”

Wirtgen India, the local subsidiary of the Wirtgen Group, is always

at hand, should there be any customer requirements: “They always

care for our needs and challenges. From time to time, they guide

our team and help. Whenever challenges arise, they are always

there.”

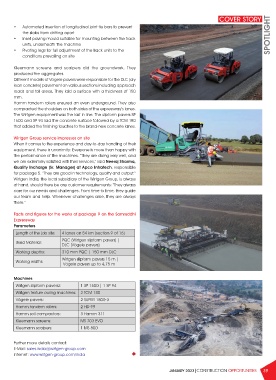

Facts and figures for the works of package 9 on the Samruddhi

Expressway

Parameters

Length of the job site: 4 lanes on 54 km (section 9 of 16)

PQC (Wirtgen slipform pavers) |

Used Material:

DLC (Vögele pavers)

Working depths: 310 mm PQC | 150 mm DLC

Wirtgen slipform pavers 15 m |

Working widths:

Vögele pavers up to 4.75 m

Machines

Wirtgen slipform paversz: 1 SP 1600 | 1 SP 94

Wirtgen texture curing machines: 2 TCM 180

Vögele pavers: 2 SUPER 1800-3

Hamm tandem rollers: 2 HD 99

Hamm soil compactors: 3 Hamm 311

Kleemann screens: MS 703 EVO

Kleemann scalpers: 1 MS 800

Further more details contact:

E-Mail: sales.india@wirtgen-group.com

Internet: www.wirtgen-group.com/india

JANUARY 2023|CONSTRUCTION OPPORTUNITIES 39