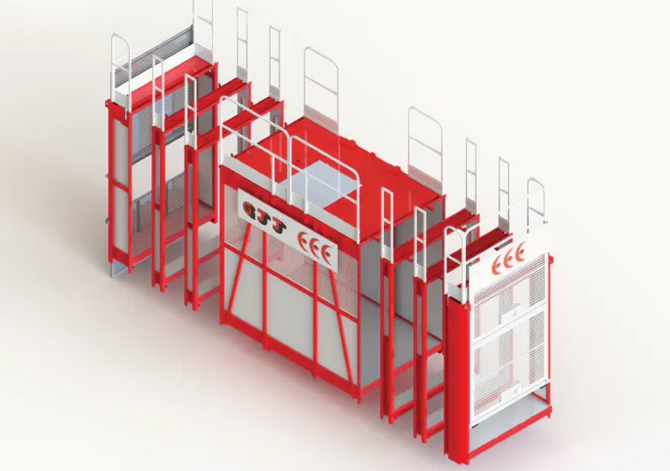

EVEREST ENGG launches Combination Type Passenger cum Material Hoist, at EXCON 2023.

Everest Engineering Equipment Pvt Ltd, launched a long-awaited and innovative product, the COMBINATION TYPE PASSENGER CUM MATERIAL HOIST, at EXCON 2023.

The Combination Type Passenger cum Material Hoist introduced by Everest Engineering Equipment Pvt. Ltd boasts a standout feature in its versatile design. Offering adjustable cage lengths of 3.2m, 3.6m, and 4.0m, along with capacities ranging from 3.2 tonnes in each cage total 6.4 tonnes on both cages together [biggest in the world with single mast operation] with 46 m/min speed to 2.7 tonnes with 63m/min speed, the hoist provides a flexible solution for construction sites. Additionally, its capability to carry 38 personnel in the 3.2t mode or 32 personnel in the 2.7t mode adds to its adaptability, eliminating the need for multiple hoists tailored to project requirements. The hoist is a much-awaited innovation with the speciality of adjustment of length, speed and the number of persons that could be carried. According to various construction site requirements, customers need not buy different hoists, they can adjust the same hoist according to their needs.

The power savings of 35-40% are already present in any GJJ passenger cum material hoist, adding another feather to it’s cap.

| Capacity | Diff. | Cage | Length |

| 3.2 Tonnes | 4.0M, | 3.6M, | 3.2M |

| 2.7 Tonnes | 4.0M, | 3.6M, | 3.2M |

Technical Details:

| 1. | Maximum Height | 500m |

| 2. | Mast Size & Material | 650x 650x 1508 mm, ST 152 |

| 3. | Motor + Gear Box | 3x15KW Nord Germany |

| 4. | PLC | SIEMENS Germany |

| 5. | VFD | 2x90KW SIEMENS Germany |

| 6. | Floor Selector | SIEMENS Germany |

| 7. | Over Load Device | Digital |

| 8. | No of Persons | 38/32 |

Speaking on the occasion, P. V. Ramdev, MD, EVEREST ENGG, said “The equipment has undergone meticulous safety testing at the GJJ R&D center, aligning with rigorous European standards. We have developed the major components at our in-house R&D centre and validated the assembly and testing according to European standards at the GJJ R&D center. The multi-level safety tests serve as a testament to the company’s commitment to delivering a secure and reliable product. By validating the hoist through comprehensive testing, Everest Engineering Equipment Pvt. Ltd assures its customers that the equipment adheres to high safety standards before being introduced to both Indian and international markets.”

The hoist’s adaptability to diverse construction site requirements positions it as a valuable asset. Whether lifting facades, handling special windows/doors, transporting large-size marbles, or serving industrial applications, it addresses a wide range of construction challenges. This adaptability makes it a potential choice for various projects, showcasing its versatility.

The company has a dedicated in-house Research and Development (R&D) center where major components of the hoist are developed. The assembly and testing processes adhere to stringent European standards, underscoring the company’s commitment to quality control and safety. By focusing on these aspects during manufacturing, the company ensures that the supplied equipment meets high standards of reliability, performance, and safety.

The initiative has played a significant role in making manufacturers self-reliant. Through the provision of incentives, favorable policies, and subsidies, the government is encouraging companies to establish manufacturing units within the country. This strategic move is designed to streamline processes, reduce regulatory hurdles, and foster an environment conducive to increased local production of construction equipment. Our vision extends beyond fulfilling domestic demands; we aspire to position ourselves as globally competitive entities. This involves a commitment to adhering to international quality standards, developing a highly skilled and adaptable workforce, and fostering collaborations with global players.

Everest Engg has bought a substantial 16-acre land parcel near Navi Mumbai, Maharashtra, where it is setting up a manufacturing facility. This facility will primarily focus on producing passenger hoists in collaboration with GJJ, manufacturing will commence in the coming 8 to 10 months.

Speaking on the demand in the Indian market, P V Ramdev, opined “We have been receiving lot many enquiries from our customers for this type of equipment. This made us do lot of research and development at our R&D centre and finally after 4 years we have come up with this product. The demand for this product is quite good both in India & abroad. We expect to sell around 120 units per year to be sold in the initial period which can gradually go up to 1500 1800 units a year.

For more details visit: www.everestengg.in